AKW experimental center provides users with free one-stop experimental site, experimental equipment, testing instruments and so on.Meet the needs of different industries, different working conditions and different materials for mixing and preparation. The experimental results can be perfectly amplified according to the ratio, and the experimental equipment is also suitable for materials with explosion-proof requirements and operating under vacuum, heating, cooling and other conditions.

The EL model range of laboratory mixers is available in sizes from 1 to 10 liters. Models EL1 EL05 EL10

Laboratory mixers of the R model series are available in sizes from 5 to 50 liters. Models R02 R04 R05 R08

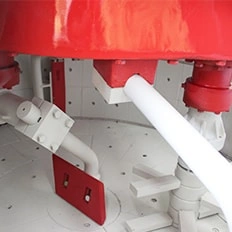

The R series of large powerful mixers are available from 100 to 7000 liters.

The AMP series of vertical shaft planetary mixers are available from 50 to 6000 liters.

Countercurrent or crossflow principle

Rotating mixing pan: for material transport

The effect: The separation between material transport and mixing process allows the speed of the mixing tool and thus the power input into the mix to be varied within wide limits

Mixing tool with variable speed: for mixing,pelletizing, kneading and many basic operations more

High efficiency: mixing, pelletizing and ball making processes are completed in the same equipment.

High rate of ball formation: particle size can be adjusted, high strength. Environmental protection: the working process is fully enclosed, no dust pollution.

Vacuum/heating/cooling process

high precision, low noise, high torque, smooth transmission, longer life

Orbital revolution + rotation superimposed on the principle of motion, reasonable mixing speed, complex motion trajectory design, so that the mixing of materials does not produce segregation, the whole mixing is more intense, more uniform, higher productivity

Auxiliary fast fly cutter, superimposed planetary stirring device, high mixing efficiency

Ceramics

Rereactory

Concrete

Glass

Metallurgy

Fertilizer

Lithium battery