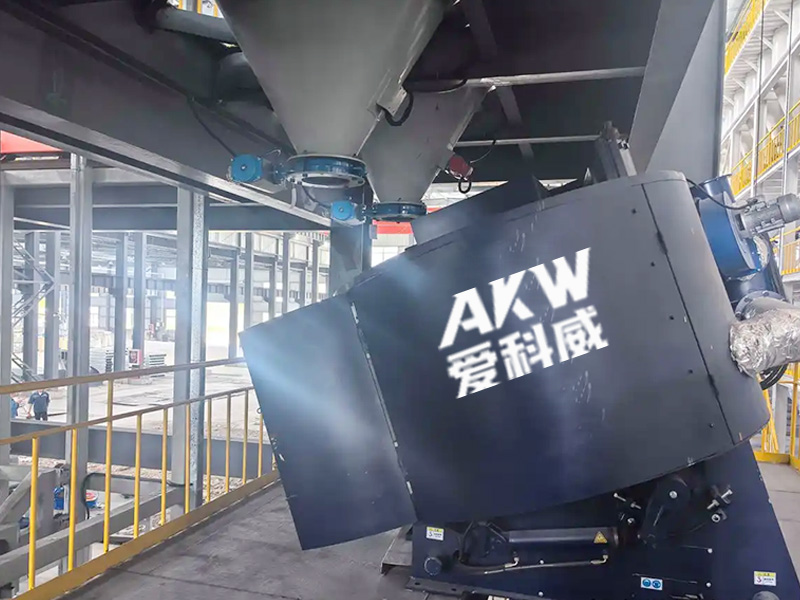

AKW inclined high-speed intensive foundry sand mixer:the innovative force of sand mixing process in the foundry industry

In the wave of the foundry industry that pursues higher efficiency,better quality and green production,sand mixing is the cornerstone of the casting process,and its efficiency directly affects the quality of castings and production costs.AKW foundry Sand Mixer Equipment+Process Design,a world-leading expert in mixing technology,is providing breakthrough solutions for domestic foundries with its innovative inclined high-speed intensive foundry sand mixer,setting off an efficiency revolution in sand mixing process.

Pain point breakthrough:The bottleneck of traditional sand mixing needs to be broken through

Foundries generally face problems such as insufficient sand mixing uniformity,low efficiency,high energy consumption,and frequent equipment maintenance.Traditional sand mixing equipment often appears to be unable to cope with increasingly complex sand formulas(such as adding multiple additives),and it is difficult to eliminate mixing dead corners,resulting in unstable sand performance,which in turn affects the finished product rate and surface quality of castings.At the same time,high energy consumption and high maintenance costs continue to squeeze the profit margins of enterprises.

AKW inclined high-speed intensive foundry sand mixer:reshaping the sand mixing standard with innovative design

AKW inclined high-speed intensive foundry sand mixer,with its unique design concept and excellent performance,directly hits the pain points of the industry:

Inclined intensive foundry mixing,efficient and uniform without dead angles:the core lies in the strong coordination of its tilted mixing container and the high-speed rotating stirring tool(rotor/paddle).This design creates violent turbulence and shearing movement,and the material is violently thrown,convected,and sheared in three-dimensional space,achieving nearly perfect micro-uniform mixing and completely eliminating dead angles.Even trace additives can be accurately dispersed.

The mixing time is greatly shortened and the production capacity is significantly improved:the efficient mixing mechanism significantly shortens the time required to achieve the target uniformity,greatly increases the processing volume per unit time,and effectively improves the overall efficiency of the production line.

Precise control of molding sand performance:excellent mixing uniformity ensures that the distribution of moisture,binder,additives,etc.in the molding sand is highly consistent,so as to stably obtain the required key performance indicators such as air permeability,wet strength,thermal stability,etc.,laying a solid foundation for the production of high-quality castings.

Energy saving and consumption reduction,lower operating costs:The efficient mixing process means shorter motor running time,combined with optimized power design,significantly reducing energy consumption per unit output.At the same time,the equipment structure is sturdy and durable,and the maintenance requirements are relatively reduced,further reducing the overall operating costs.

Cleaning and convenience,strong adaptability:The inclined design is convenient for unloading and has less residue;at the same time,the equipment is easy to clean,meeting the needs of switching between different sand molds(such as clay wet sand,water glass sand,resin sand,etc.).

Customer testimony:Visible efficiency improvement

A well-known domestic automobile casting manufacturer,after introducing the AKW inclined high-speed and intensive foundry sand mixer to replace the old equipment,has seen significant changes in production data:

The sand mixing cycle has been shortened by nearly 40%,and the production line efficiency has been greatly improved.

The fluctuation range of the sand performance has narrowed by more than 50%,and the scrap rate of castings has been significantly reduced.

The unit energy consumption has been reduced by about 30%,saving considerable electricity bills annually.

The equipment failure rate and maintenance time have been greatly reduced,ensuring the continuity of production.

The project leader said:"AKW high-power mixer not only solves the problem of sand mixing uniformity that has troubled us for a long time,but its high-efficiency and energy-saving characteristics also bring tangible economic benefits.It is a intensive foundry tool to enhance core competitiveness."

Leading the future:Empowering intelligent and green casting

As the foundry industry moves towards intelligence,greenness,and high-end,the requirements for basic process equipment are becoming increasingly stringent.AKW inclined high-speed high-power sand mixer is becoming the preferred equipment for more and more foundry companies to upgrade their processes and enhance their core manufacturing capabilities with its excellent mixing quality,efficient productivity,excellent economy and reliability.

AKW ntensive foundry sand mixer Equipment+Process Design has been deeply involved in the field of mixing technology for many years and is committed to providing the most advanced solutions to customers around the world.The successful application of AKW inclined high-speed high-power sand mixer in the foundry industry demonstrates its firm commitment and strong strength in promoting industrial technological progress and helping customers reduce costs and increase efficiency.